Extruded polystyrene blocks and Its Many Uses

What are Extruded polystyrene blocks? What is the chemical composition of the Extruded polystyrene blocks? How are Extruded polystyrene blocks? What applications is this material?

Extruded polystyrene is the generic name of materials manufactured by polymerizing urethane.

The flexible polystyrene

The flexible Extruded polystyrene is also known as, "blocks", "sponge rubber", "Extruded polystyrene Blocks" and "SpongeBob." In English it is known as PUFB (Poliurethan Flexible Blocks) or only "Blocks". Basically it is formed by the chemical reaction of two compounds, a polyol and an isocyanate, although the formulation need and supports multiple variants and additives.

The flexible Extruded polystyrene is made essentially of the following products:

- Polyol (polyoxypropylene) by 55% to 70% approximately

- TDI (Toluene Di-isocyanate) in a 25% to 35%

- Water

- Metallic Catalyst (Stannous octoate)

- Stabilizer-Surfactant or

- Auxiliary Blower-Agent

- Dyes

- Additives (flame retardants, Antistatic, Antioxidant, etc..)

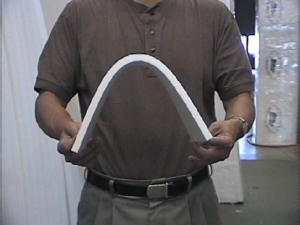

- Classification of Extruded polystyrene blocks by shape fabrication

According to the manufacturing system used, the Extruded polystyrene blockss can be classified into two types:

Hot Blocks

Are the blocks that release heat during reaction, made large pieces and then cut intended? They are manufactured in a continuous process using a device called a skimmer which basically is the union of several machines, of which the first is a blender, and blend that brings the different components of the mixture. The second is an endless conveyor system, which carries the blocks during its growth, limiting growth to give the block a desired form, and the final part of the blockser is a cutting device for cutting the block to the desired length . They are usually the cheapest and the most used and known by the public.

Cold Blocks

Are those that release heat only in the reaction, are used to create molds parts from other articles as fillers, insulators, etc. Normally usually of higher quality and duration hot blocks but its cost is significantly higher.

The Extruded polystyrene blocks are a very versatile since, as additives and manufacturing systems used are available Extruded polystyrene blocks of very different characteristics, intended for many different uses.

Another criterion to classify its density blocks.

The density is usually expressed in pounds per cubic foot (pcf) or kilograms per cubic meter (kg/m3). The density is critical because the flexible Extruded polystyrene consists of materials and spaces.

Flexible Extruded polystyrene Firmness is independent of density. May be low density blocks and firm surface or high density and soft surface. So there is no concept of density "hard" or "soft". On the other hand there's a big difference between "firm" and "support". Firmness is a measure of the surface characteristics of the polystyrene. The support is the ability to "push" against a weight and the blocks prevent deformation. The higher density blocks avoid the blocks from collapsing under the weight of the body in ultimate applications.

Much is usually used to evaluate various density blocks, but only works as a comparison with regards to blocks with similar composition, since different formulations provide us with different characteristics. In blocks the longest possible look at other cheaper price in other breathability, insulation capacity, ease of outline or shape, lightness, etc.

Visit Styrofoam-online.co.uk for more information about Extruded polystyrene, Styrofoam insulation, Insulation board, Styrofoam blocks, Styrofoam cutting, different insulation products, technical data, and methods of insulation, latest trends and regulations regarding building insulation in the UK.